WELCOME

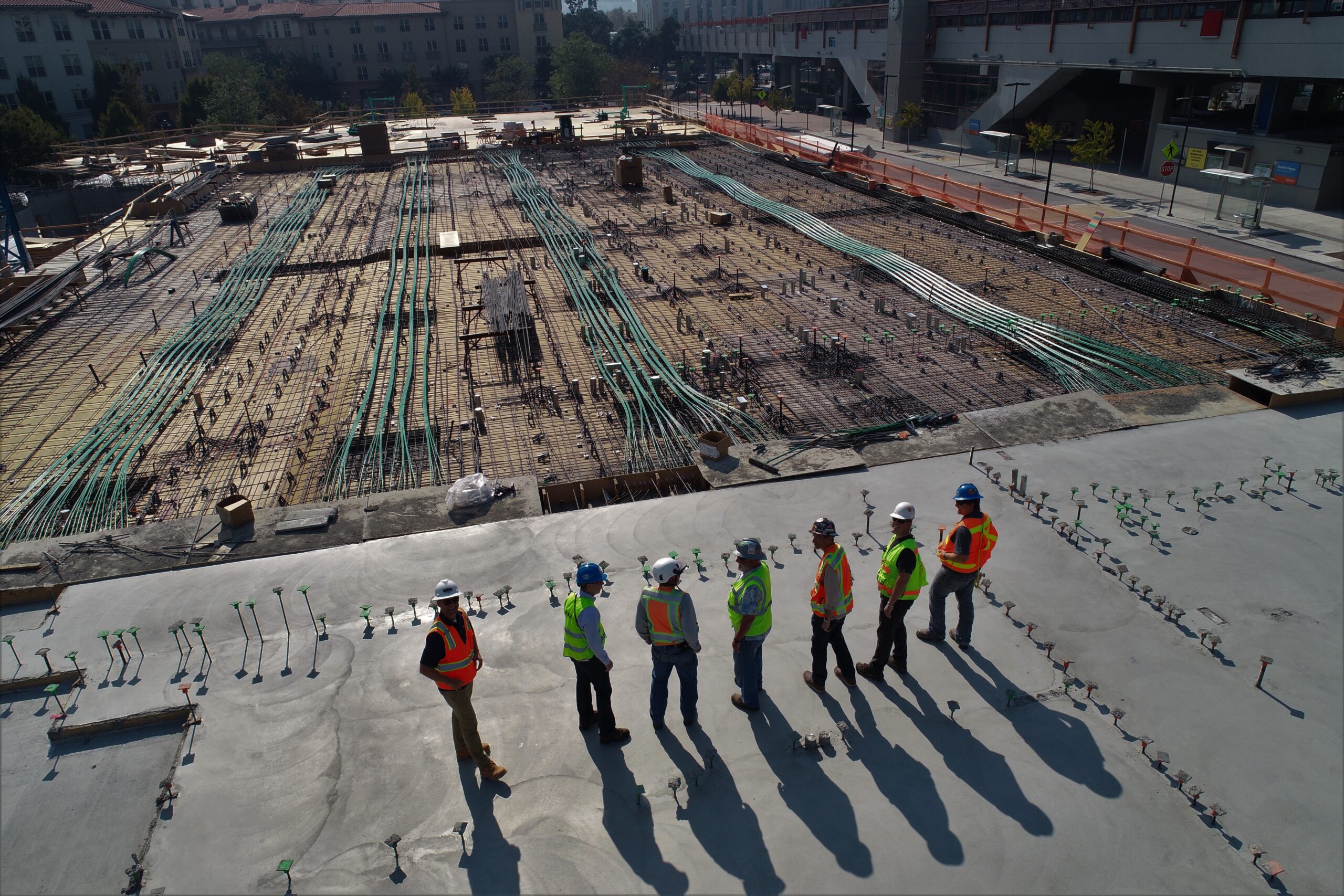

Since 1989, Polyseal has been the preferred provider of specialist services across the construction industry.

It is our commitment to our customers that has led to the company’s growth and continued success.

OUR PROJECTS

More than 30 years experience

The varied nature of our specialist services has exposed our people to all major industry sectors including major construction, infrastructure, and mining and has enabled us to develop expertise in the use of a wide range of construction products and chemicals.OUR SERVICES

Specialists in our field

From a background in waterproofing new and existing structures using a variety of materials and techniques, Polyseal has grown its repertoire to include a wide range of services.services

Our Services

BUILDING REPAIR

& REFURBISHMENT

PROTECTIVE

COATINGS

FIRE SAFETY

UPGRADES

STRUCTURAL

STRENGTHENING

ALL

SERVICES

Policies & Accreditations

Who We Are

1000

+ PROJECTS

200

+ HAPPY CLIENTS

15

+ ACCREDITATIONS

4

LOCATIONS AUSTRALIA WIDE

our clients

Who We Work With